First, product application

The UVLED point light source is suitable for application in large-scale production enterprises and also suitable for small-scale experiments in university laboratories and research institutes. UVLED point light source is used in industrial adhesive, printing and packaging, optical fibercommunication, medical photoelectric, electronic assembly, paint drying, code printing, loudspeaker, camera module, LCD screen bonding and other related industries.

Second, product features

3.1 small size, it can be easily integrated into the automatic assembly process, easy to carry.

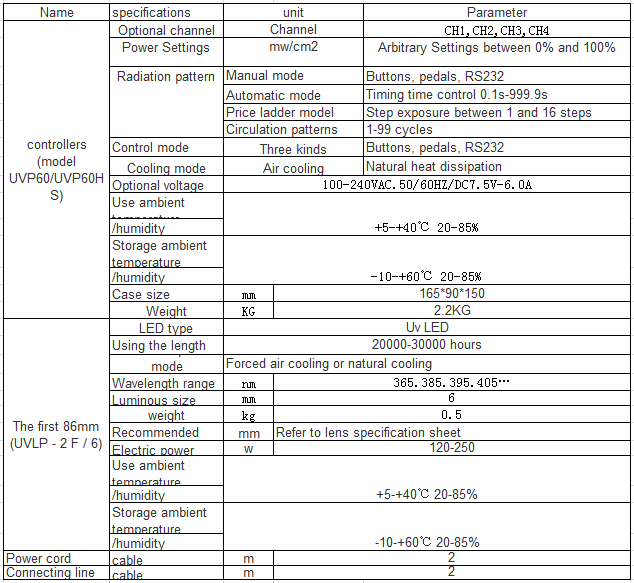

3.2 a host can control four channels, and each channel can be controlled independently or jointly; Time, power, mode, flexible setting, perfect embodiment.

The curing time of each channel can be set between 000.0 s and 999.9 s according to the curing time.

The power size of each channel is arbitrarily set between 0% and 100%;

Each channel can be set in three modes: manual mode, automatic mode and advanced mode:

Manual mode: power setting is available;

Automatic mode: power and countdown time can be set;

Advanced mode: you can set the number of steps (steps can be set between 1-16 steps), and the number of cycles can be set between 1-99 cycles.

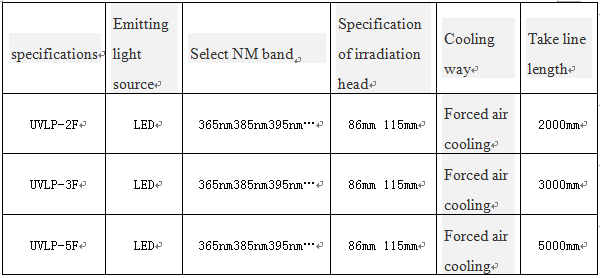

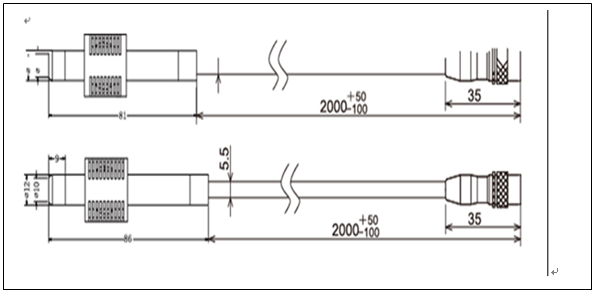

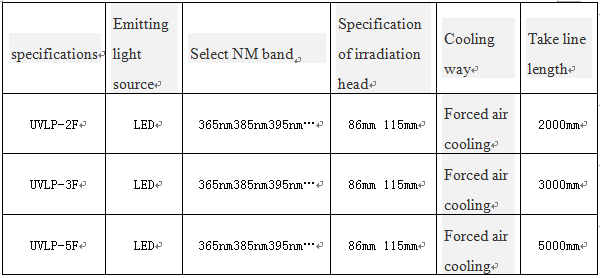

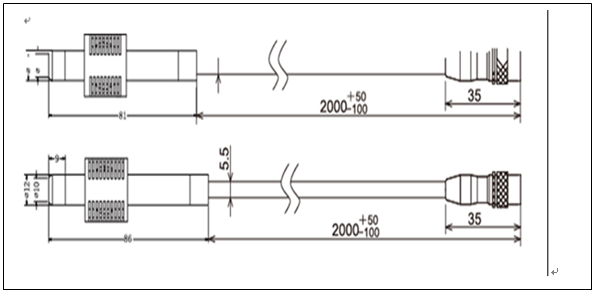

3.3 According to the classification of irradiation head, point source can be divided into two types: one with fan and the other without fan. (fan irradiation head 86 mm, 115 mm, without fan irradiation head 60 mm, 85 mm, 118 mm) line length specification is 2M, 3M, 5M.

3.4, the service life of point light source is long, for example, the service life of UV lamp is about 2000 hours, while the estimated life of UVLED is about 20000 hours, which is about 10 times of that of lamp, and the overall performance-price ratio is very high.

3.5. There are various control methods, not a single one. Specifically, there are the following control methods: key control, foot control, I/O signal interface control, easy control;3.6. The protection of UVLED is relatively safe. When the temperature is too high, any lamp beads are damaged, or the heat dissipation device fails, a buzzer will sound to stop the work, so that the staff can take measures as soon as possible to ensure safety.

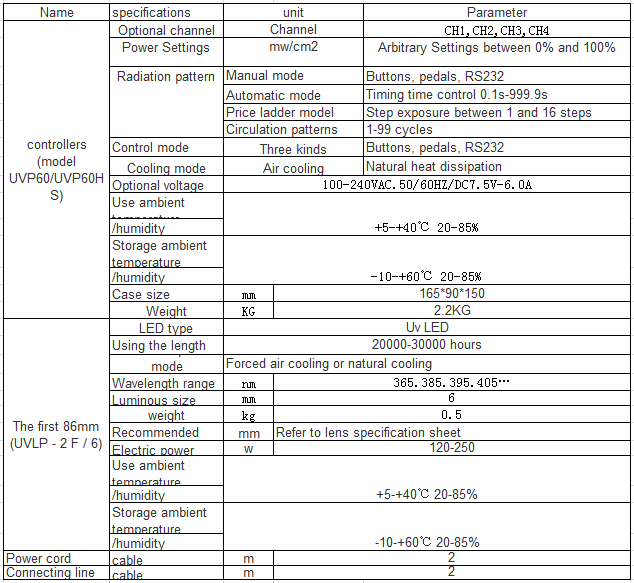

Third, controller function and parameters

Other specifications are as follows:

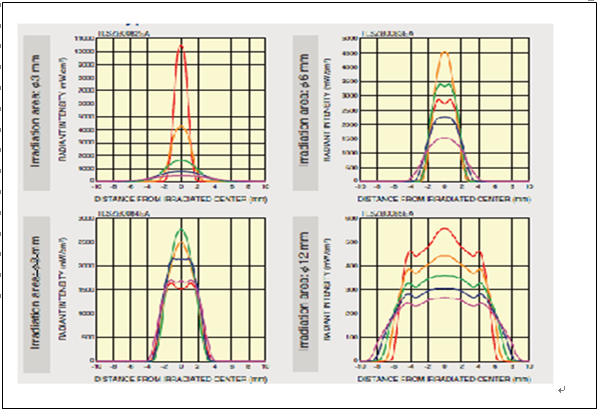

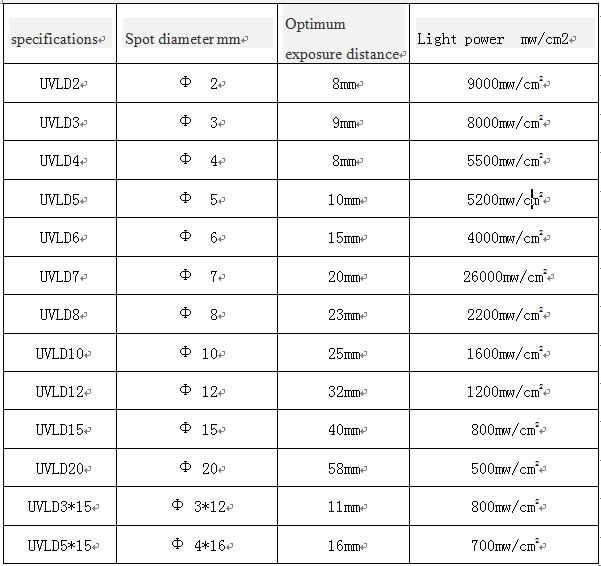

Four. Specification and power of irradiation head

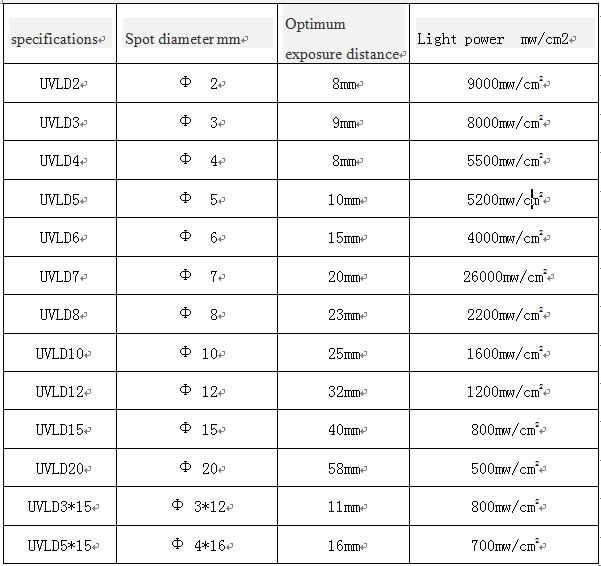

Five, optical lens specifications

全国服务热线

全国服务热线